Manufacturer of conveyor belts and rubber reinforcement materials

PRODUCT

Product Details

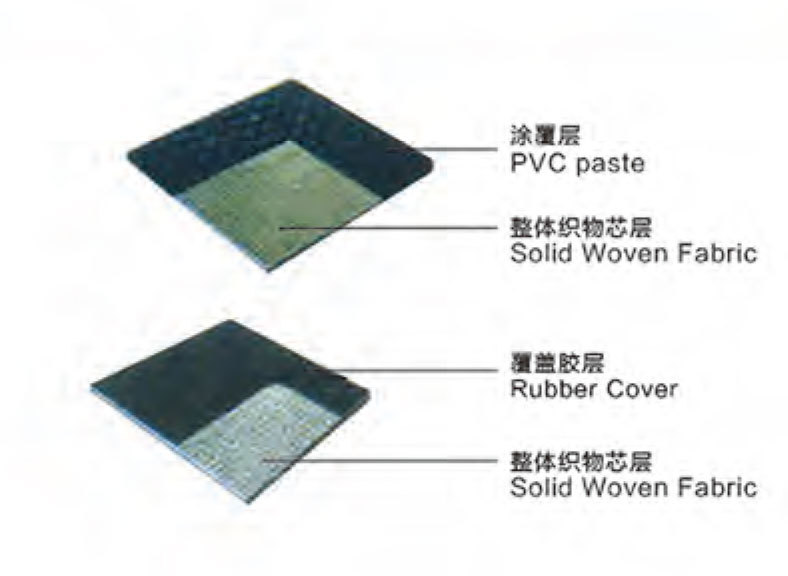

The Solid Woven Conveyor Belt is made from plastifly or vulcanization of whole belt carcass in the polyvinyI choride solution.It has the advantages of high strengh,heavy load,and stable conveying performance, besides,this belt also have followingfeature:fire resistant,anti-static,abrasion resistant and corrosion resistant.

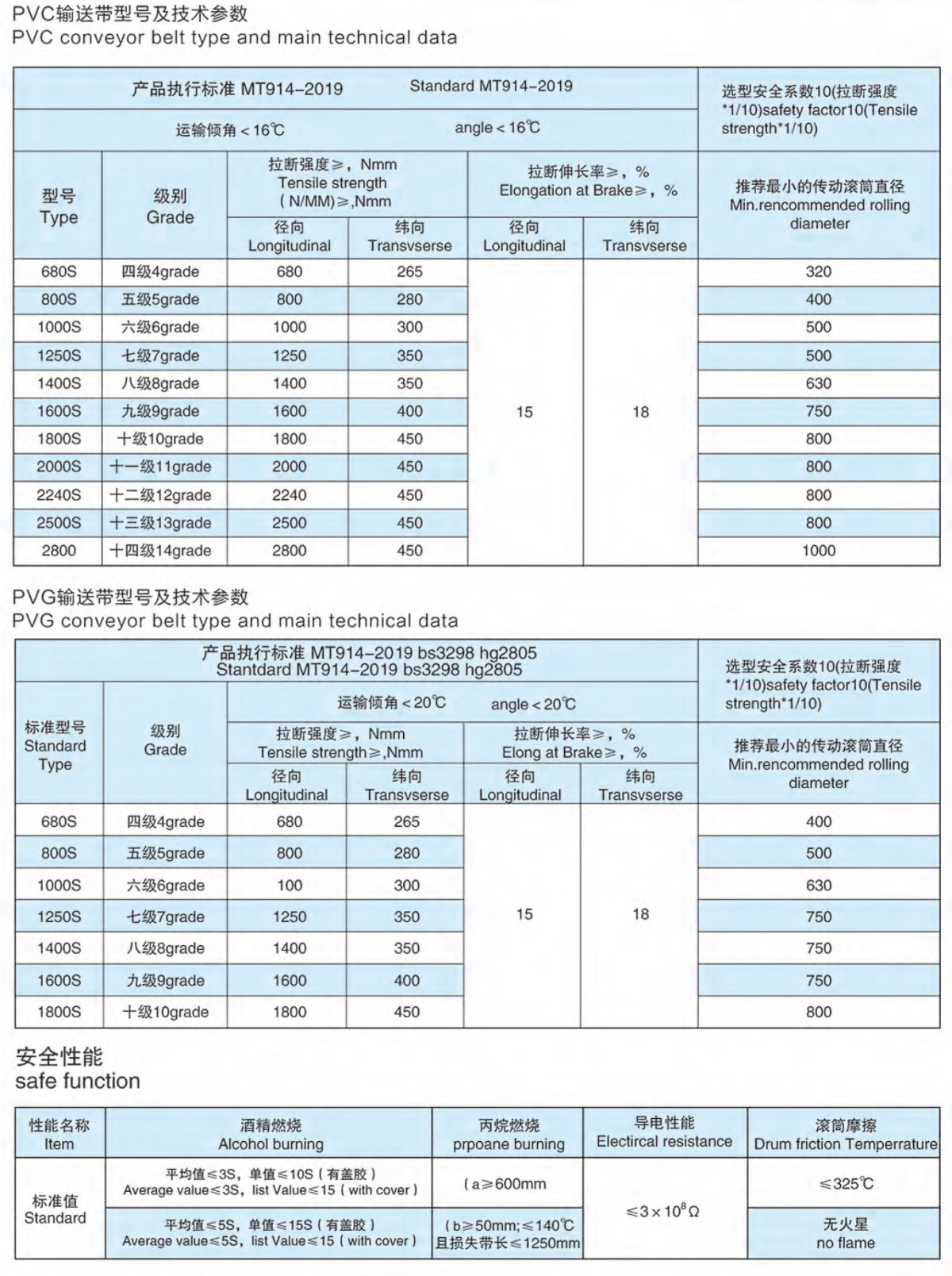

It is mainly used for underground material conveying in the coal mine,also for the material conveying of metallurgy and chemical industry;it contains two types:PVC and PVG.

For PVC belt, top rubber and bottom rubber are PVC coating cover, Single-Sided cover rubber thickness not less than 1.omm:For PVG belt,top rubber and bottom rubber are nitrile rubber and PVC, single-sided cover rubber thickness:1.5mm-4.5mm.Common PVC type belt is suitable for dry occasions with dip angle no more than 16 degrees; PVG type belt is suitablefor wet occasions with dip angle below 20degrees.

FAQ

SERVICE OBJECTIVE

CUSTOMER FIRST,WITH CUSTOMER SATISFACTION AS THE SOLE CRITERION FOR MEASURING ALL WORK

SERVICE ITEMS

1.PROMOTE AND INTRODUCE OUR COMPANY AND PRODUCTS TO CUSTOMERS, HELPING THEM UNDERSTAND THE COMPANY AND ITSPRODUCTS

2 PROVIDE PFE-SALES CONSULTATION TO HELP CUSTOMERS SCIENTIFICALLY ANALYZE AND REASONABLY CHOOSE THE TYPE ANDSPECIFICATIONS OF CONVEYOR BELT PRODUCTS.

3.ASSIST CLENTS IN FORMULATING JOINT SOLUTIONS, PREPARING JOINT TOOLS AND ADHESIVES, AND PROVIDING PROFESSIONAL

TECHNICAL GUIDANCE.

4. PROVIDE ADHESIVE BONDING SERVICES FOR CONVEYOR BELTS.

5. PROVIDE INSTALLATION AND DEBUGGING SERVICES FOR CONVEYOR BELTS.

6. TRAIN CONVEYOR BELT BONDING TECHNICIANS FOR CUSTOMERS.

7. PROVIDE DAMAGE REPAIR SERVICES FOR VARIOUS CONVEYOR BELTS.

8. ACCEPT CUSTOMER CALLS, LETTERS, VISITS, AND COMPLAINTS SERVICES.

9. ESTABLISH CUSTOMER QUALITY TRACKING FILES AND CONDUCT REGULAR TELEPHONE FOLLOW UPS.

Operation&Maintenance Manual of Rubber Conveyor Belt

1. Direct sunlight or drenching should be avoided during conyeyor belt in trans and in storage.Prevent the contact withsubstances such as acid,alkaline and oils an organic solvenl and so on.and rubber belt should be placed over one meter away from a heat source.

2. The warehouse temperature should be fanging-18'C-40'C,and the reative humidity During 50-80%storage.

3. The products should be palced by rolls and should not be enfolded.

4. They should be turned and moved once a quarter dutring storage.

5. Conveyor belts of different type, specs and layer Should not be spliced and used.For splicing,the best way is viaagglutination method.

6. The matching of drive durm diameter and the number of bell layers,the collocation of the drive drum withturnaboutdrum,and the requirement on the well,angle of carrying roller should be stipulated in accordance with the conveyor designand selected reasonably.

Message

Recommended Products

从这里搜寻

获取免费报价